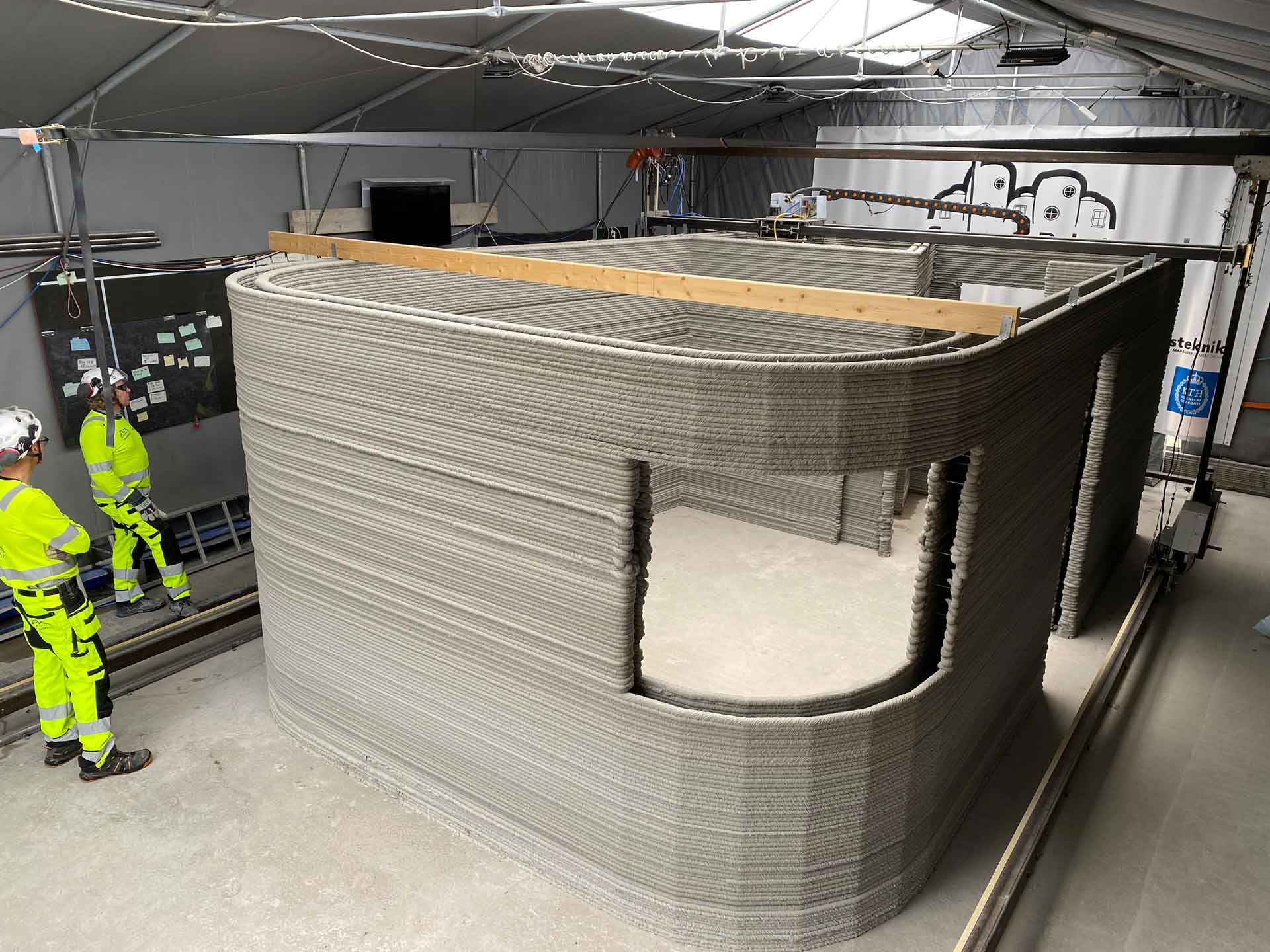

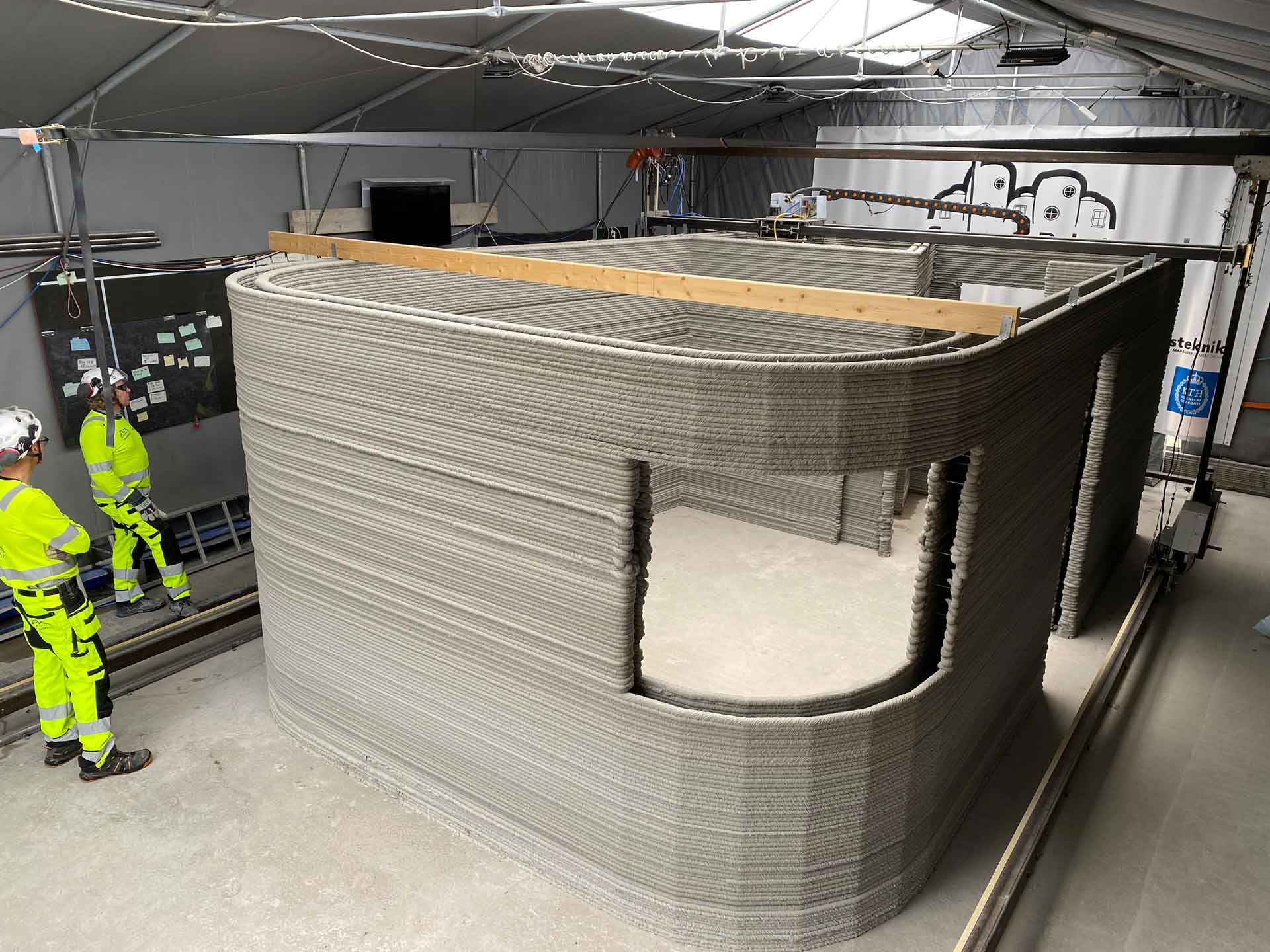

Sweden’s first 3D-printed house

In Tumba, south of Stockholm, Sweden’s first 3D-printed concrete house was recently fabricated on the premises of Heidelberg Materials' ready-mixed concrete subsidiary Betongindustri. The building material used was i.tech 3D, Heidelberg Materials' special mixture for 3D concrete printing.

The tiny house, just 24 square metres, was completed in June and offers all the amenities of home: a living room, a bedroom, a kitchen and a bathroom with shower. It features 50 mm thick double walls, in between which is insulating material.

3D printing – fast and versatile

“Effectively, it took about 28 hours to print the house – because we are still mixing the concrete manually at the moment. Once the process is up and running at industrial scale, I expect we’ll be able to print a similar house in about 12 hours,” said Tobias v. Haslingen, managing director and co-founder of developer ConcretePrint.

The printer uses high-tech “i.tech 3D”, which was specially developed for 3D printing by Heidelberg Materials subsidiary Italcementi and is suitable for creating a broad array of shapes with various types of 3D printers.

The only part of the house that is not printed is the roof, which is still built the conventional way. The Tumba Tiny House is intended as a prototype that will be used for future marketing and demonstration of the on-site printing method.

“We’ve had our ups and downs, but we are at a point now where we can say that we are satisfied with the 3D printer prototype,” added Tobias v. Haslingen. “By the end of the year, we will print another larger model in Sweden that will be 15 metres wide, 20 metres long and 10 metres high.”

Heidelberg Materials leading the way in 3D-printed homes

3D-printed houses that are ready for occupancy have already been built in Germany: In autumn 2020, residential buildings were printed in Beckum (North Rhine-Westphalia) and Weißenhorn (Bavaria), which have already been occupied or are being used as showcase homes. The house in Tumba is now the first of its kind in Sweden.

“Without the commitment of Betongindustri and Heidelberg Materials, this project may have never got off the ground,” said Tobias v. Haslingen. “In addition to providing land, building materials and equipment, they also supported the project with know-how about the properties and structural aspects of concrete. We were in close contact with Dr. Jennifer Scheydt from Heidelberg Materials, who had been significantly involved with the projects in Germany.”

ConcretePrint’s 3D printer is currently designed to print in dimensions up to 9 metres long, 4.2 metres wide and 2.5 metres high. But work is already underway on a larger printer and the software is being further developed.

3D concrete printing: resource-saving and efficient

“There is a lot of talk about digitalisation in the construction industry,” according to Per Berglund, CEO of Betongindustri. “This project is a very good example of that, and we aim to actively promote innovation in this field.”

He called the further development of the market hard to predict, but said it was clear that there is great potential in 3D concrete printing. “Two-thirds of the time spent on pouring concrete is taken up by erecting and preparing the formwork. If you can eliminate that, you’ve gained immensely,” said Per Berglund, adding: “3D-printed houses are resource-saving, which lends even more efficiency in terms of material use.”

With their comprehensive knowledge of cement and concrete, the expert teams of Heidelberg Materials' global R&D functions will thus continue to provide high-quality products and technical know-how to architects, builders and companies wishing to produce houses or concrete elements with 3D printers in the future. Their common goal: To adapt the traditional building material concrete to the possibilities offered by digitalisation.

Printing a 3D Tiny House in Tumba/Sweden.

Tobias v. Haslingen, Managing Director and developer of ConcretePrint.

3D-printed wall Tumba/Sweden.

3D printed house in Beckum, Germany.

Detlef Pedohl

3D-printed Tiny House in Tumba/Sweden.

3d printing structure tiny house sweden.

Printing a 3D Tiny House in Tumba/Sweden.

Tobias v. Haslingen, Managing Director and developer of ConcretePrint.

3D-printed wall Tumba/Sweden.

3D printed house in Beckum, Germany.

Detlef Pedohl

3D-printed Tiny House in Tumba/Sweden.

3d printing structure tiny house sweden.