Smart-built wind turbines

How combining digital solutions and sustainable building materials brings real customer benefits

Rokas Mulevičius walks around the base of a wind turbine. He is the director of commerce at PST – Panevežio Statybos Trestas, a Lithuanian construction company with over 60 years of experience. They are known for their infrastructure development and environmental improvement within the Baltic country. PST's recent project was the construction of the concrete bases for 10 turbines in a wind turbine park in a rural area of Akmene district. The bases are an unseen but critical part of the construction of each turbine.

Standing out from the competition

PST needed a strong partner for this project. What stood out for Rokas Mulevičius about Heidelberg Materials Lietuva was its innovative solutions combining sustainability and digitalisation. Heidelberg Materials offered a low-carbon concrete. Additionally, Heidelberg Materials was able to calculate and simulate concrete heat and cracking risk parameters in advance to get upfront quality assurance of the concrete performance to minimise project risks. No other company could offer anything like this in Lithuania.

The sustainable and digital solution that delivered results

EcoCrete Smart is the name of a new set of solutions offered by Heidelberg Materials in a few pilot markets, including Lithuania. EcoCrete is a low-carbon concrete which provides a reduction of CO₂ emissions by up to 20% compared to regular concrete. Its high performance and durability are nevertheless maintained. The addition of “Smart” refers to EcoCrete being paired with SmartRock sensors for accurate concrete strength testing and real-time remote temperature monitoring. Another “Smart” solution used in the project included digital delivery planning and remote quality assurance tools.

“By using EcoCrete Smart, we were able to receive an economically better offer which was accomplished by using special cement types. Due to the concrete parameters simulation and real-time temperature monitoring, we were able to observe and control critical phases after the casting of the concrete”, said Rokas Mulevičius.

Establishing the base for a future and sustainable partnership

The total project volume was more than 10,000 m³ of concrete for the bases of the 10 wind turbines. To deliver the ready-mixed concrete to the construction site, a mobile plant was installed close by. Choosing EcoCrete Smart and using a mobile plant together allowed for better control over both the delivery of the concrete and its quality. It provided the PST team the chance to use these new solutions and equipment, and get trained on the construction of wind turbines, from the supply chain to temperature control and isolation after concreting.

When thinking about the future, Rokas. Mulevičius says, “We strongly believe that digital tools and more focus on sustainability is the way to move forward. Therefore, we would encourage others to take smart decisions when choosing suppliers.”

Windfarm Akmene One: Wind turbine foundation.

Heidelberg Materials

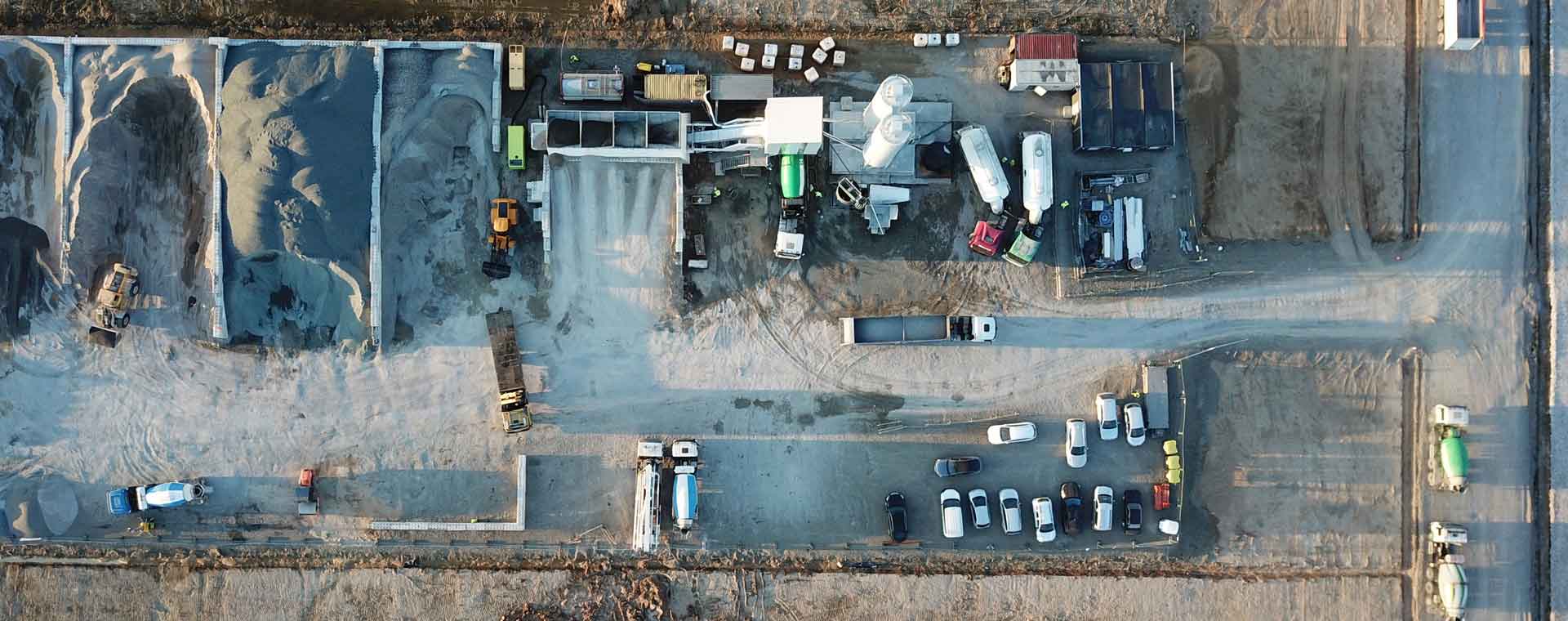

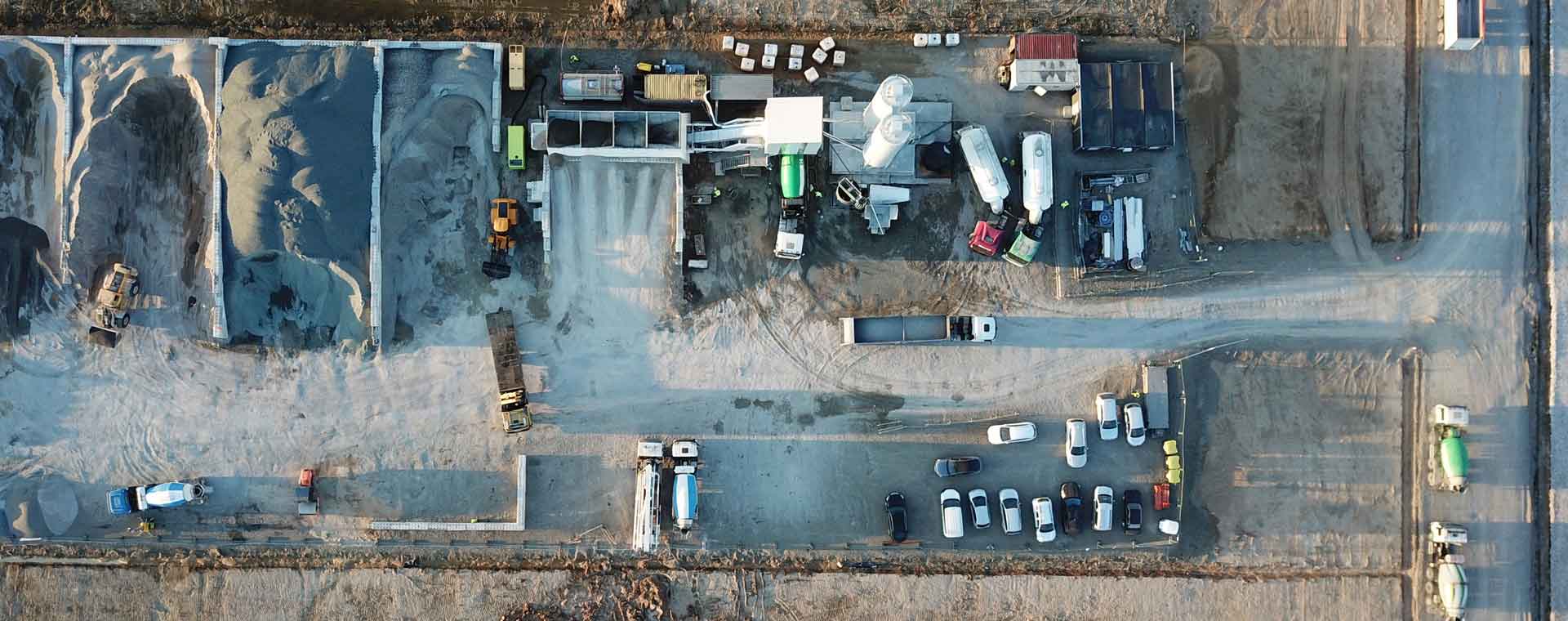

Windfarm Akmene One: Bird's eye view of the construction site.

Heidelberg Materials

Windfarm Akmene One: View from other side.

Heidelberg Materials

Windfarm Akmene One: Wind turbine foundation.

Heidelberg Materials

Windfarm Akmene One: Bird's eye view of the construction site.

Heidelberg Materials

Windfarm Akmene One: View from other side.

Heidelberg Materials